TOP-ONE CF502

Innovative Product!! Eco-friendly Offset Print Super Technology

Photocatalytic reaction device is built-in and it activates dampening water.High-quality print is possible without using conventional chemical.

Photocatalytic reaction device is built-in and it activates dampening water.High-quality print is possible without using conventional chemical.

We support “Eco-friendly Offset Print”.

This system removes calcium and magnesium from tap water, and significantly reduces its surface tension. You get a better print quality at lower cost, since no conventional chemical but only tap water is needed. (Condition differs from printing environment.)

Ultimate chemical free system was completed by integrating the combination of photocatalytic water processing unit and magnetic water processing unit, and Cosmotech’s manufacturing technology of dampening solution circulation system. TOP-ONE CF502 contributes “eco-friendly offset print”.

Features

- No conventional chemicals required for dampening water.

- Waste liquid is reduced and be an eco-friendly printer.

- The ink mileage improves because minimum water is used for print.

- No damage to CTP plates and rollers.

- Sewage drainage is possible since chemical isn’t contained.

(Confirmation by an ingredient analysis is necessary for sewage drainage.)

Chemical free system

Photocatalytic Water Processing Unit

By using photocatalytic reaction by oxidation titanium and a UV lamp, dissolved oxygen in the water is reduced and the oxidation-reduction potential of water is lowered. This regenerated water is expected “decomposition of dirt”, “antibacterial activity”, “antiseptic property” and “harmful substance removal”. Also, osmotic strength to hydrophilic non-image part of PS plate becomes high by a decline of the surface tension. Even if ink mixes with dampening water, because chemical isn’t contained, chemical reaction isn’t initiated and a phenomenon of variation in ink thickness by color doesn’t occur. By this, it is possible to maintain the most suitable balance of dampening water and ink, and higher quality of print can be achieved by small amount of dampening water and ink.

Magnetic Water Processing Unit

Magnetic water processing unit has the effect of settling red rust and impurities in the water down to the tank lower part. So it prevents scale and dirt from accumulating on the circulation system (piping system, circulation tank, printing press). TOP-ONE ECO CF502 removes residue deposited already in the printing system little by little. The endurance of the longer effect can be expected by installing a dampening water filtering system PC-500D.

Also, it has the effect of subdivision of water particle (1/13). By synergistic effect with photocatalyst, surface tension falls and ability to penetrate increases.

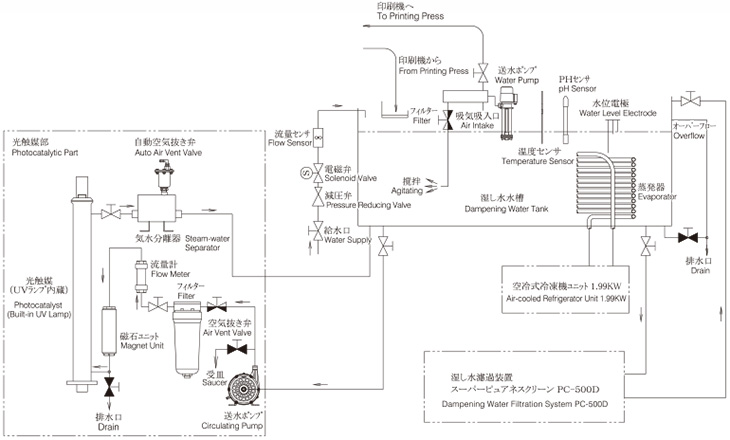

System Flow Chart

*Filtration system PC-500D needs to be installed to make the system perform effectively.

(Note: A combination with a filtering system manufactured by other company can’t guarantee the effect.)

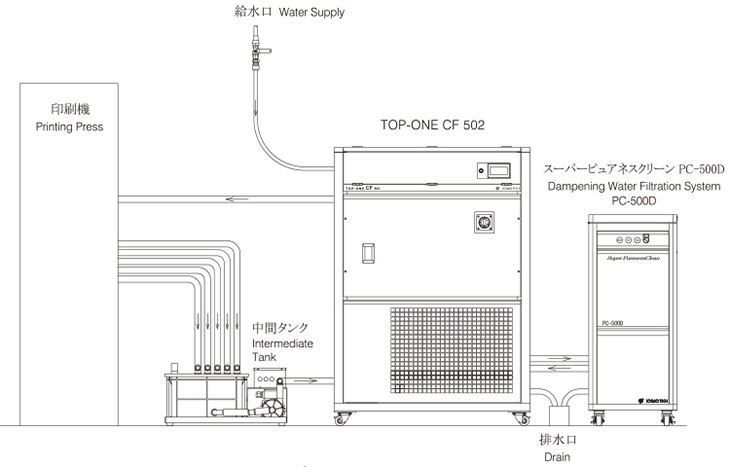

System Configuration Diagram

*Filtration system PC-500D needs to be installed to make the system perform effectively.

(Note: A combination with a filtering system manufactured by other company can’t guarantee the effect.)

Effect & Experimental Proof

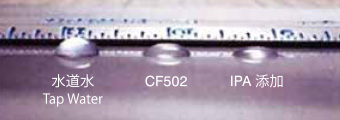

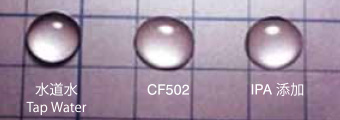

Surface Tension of Water (Comparative Picture)

Left “Tap Water” / Middle “CF502” / Right “Addition of IPA”

Without using additive agent it becomes hydrophilic, and the surface tension is lowered.

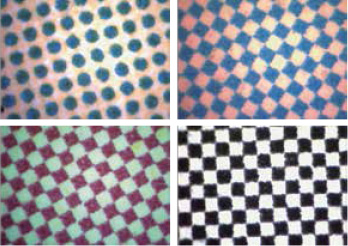

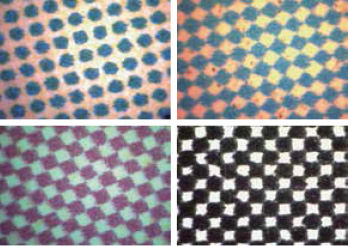

Printing Dot (Comparative Picture)

Left “CF502” / Right “Addition of IPA”

Photos are magnified the same design 200 times. Image reproducibility

from highlight to shadow rises remarkably, and the printing quality improves.

CF502

Addition of IPA

Cost Performance

40” 5 color press Day shift operation

| Days of operation for 1 month | 25 days |

|---|---|

| IPA | JPY3,000/ can |

| Days of operation for 1 year | 300 days |

| Etch solution | JPY16,500/ can |

| Industrial waste disposal rate | JPY90/ litter |

Before Installation

| Usage of IPA | 18 litter x 1 can/ day → 12.5 cans/ month 1 can JPY3,000 x 12.5 = JPY37,500/ month JPY450,000/ year |

|---|---|

| Usage of Etch solution | 20 litter x 4 cans/ month 1 can JPY16,500 x 4 = JPY66,000/ month JPY792,000/ year |

| Amount of waste liquid | 150 litter x 4 times (Water exchange once a week) → 600 litter/ month Industrial waste disposal cost JPY90/ litter x 600 = JPY54,000/ month JPY648,000/ year |

| TOTAL | 450,000 + 792,000 + 648,000 = JPY1,890,000円/ year |

After Installation

Cost of chemical and industrial waste disposal cost can be reduced substantially.

(When certain conditions are reached)

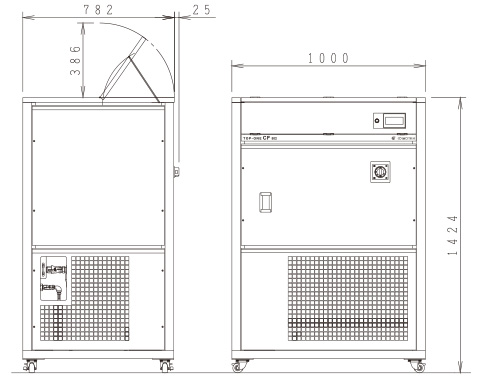

External Dimensions

Specifications

| Description of Product | Chemical Free Dampening Water Circulation System |

|---|---|

| Model | TOP-ONE CF502 |

| Configuration | Photocatalytic Apparatus, Cooling Water Tank and Air-cooled Refrigerator |

| Setting and Error Display | Photocatalytic Apparatus, Cooling Water Tank and Air-cooled Refrigerator |

| Power Supply | 3-phase 200V 50/60Hz |

| Electric Capacity/ Current | 5.9KVA/16.8A |

| Tank Capacity | Approx. 135L (Fixed Quantity 100L) |

| Refrigerator Output | 1.99KW |

| Cooling Capacity | 6.1/7.3KW |

| Refrigerant | R407C |

| Water Pump | 180/ 250W 50L/min (Pump Head 4m)/ 80L/min (Pump Head 4m) |

| Circulating Pump | 170/265W |

| Water Supply Method | Automatic (Water Tap Direct Connection) |

| Etch Solution Control | Fixed Quantity Dilution by a Bellows Pump |

| Dimensions (W x D x H) | 1000×782×1424mm |

| Weight | Approx. 300kg (In Operation: Approx. 400kg) |

| Applicable Press | 26” 8 Color ~ 44” 4 Color or Less |

Specification may be changed without notice.