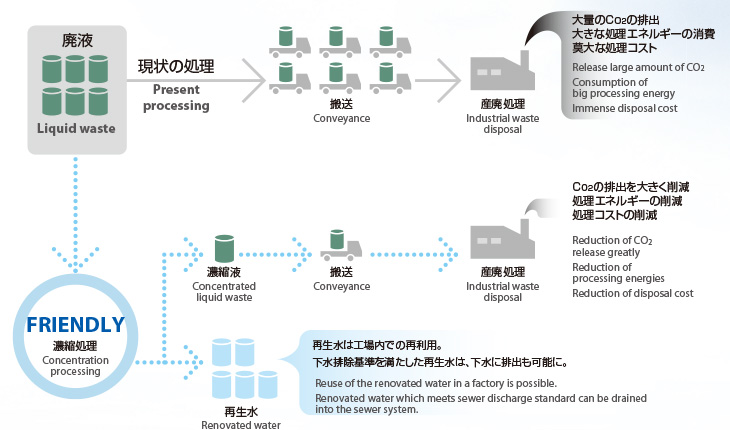

FRIENDLY

When a company works, it has forced a sometimes big duty and responsibility, and a great burden of expense although the keyword “environmental protection” is imaged with a thing required for the society and the earth of the future, and gentle to. Processing of the liquid waste generated in a production activity and recovery expense are also the one.

COSMOTECH aids the corporate activity which carries out philanthropy of the “FRIENDLY” from three sides of through, environmental protection, safety, and economical efficiency.

Amount of discharge of wastewater is reduced sharply

Conventionally, wastewater generated in a production site has been processed by requesting to an industrial waste disposal company.

The amount of wastewater in which an industrial waste disposal company takes over such a present condition is sharply reducible by introducing FRIENDLY without spending big expense.

A safe and efficient processing system

As a feature of FRIENDLY, safe and efficient processing by the “reduced-pressure distillation method*” which does not use fire is possible, and unusual odor processing and generating of toxic substance by heating is also very few.

* Distillation under reduced pressure lowers boiling point of water and it makes water to be boiled at a low temperature by making pressure lower than ordinary pressure.

High Processing Ability

- High concentration rate is realized and industrial waste disposal cost is reduced sharply.

Actual performance records: Water-soluble wastewater can be condensed to a maximum of 1/20. - Various water-soluble wastewater can be processed.

Processing past records: CTP developer waste, varnish washing waste, dampening solution waste, flexo washing waste, cutting oil waste, painting waste, food waste, etc.

Convenience and economical efficiency

- The only required things are a little electricity and antifoam agent.

- Mitigation of labor load by 24-hour continuation automatic operation.

- Automatic cleaning function of the vacuum concentrating kettle.

- Improvement in the operativity by a touch panel.

- Compact design which doesn’t choose a place of installation.

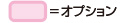

Structure of FRIENDLY

① Wastewater is sucked into the kettle.

② Internal pressure of the kettle is decompressed.

③ The kettle is heated and boils at low temperature.

④ Antifoam agent is added in order to press down bubble generated during boiling.

⑤ Steam flows into a refrigerator. It is cooled and changes to clean water.

⑥ The concentrated wastewater remaining in the kettle is collected in the concentrated wastewater tank after going through several rounds of concentration.

⑦ Clean water is accumulated in the internal tank of the main unit then sent to the external tank.

⑧ Clean water in this external tank is sucked into the kettle during cleaning mode.

OPTION

a) Liquid waste intermediate tank

b)Renovated water intermediate tank

c)Concentrated liquid waste intermediate tank

d)Renovated water pH display

e)Renovated water pH control

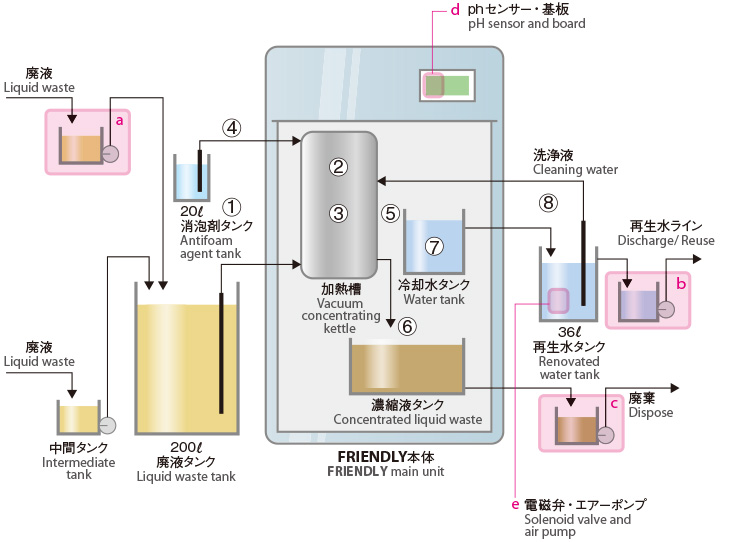

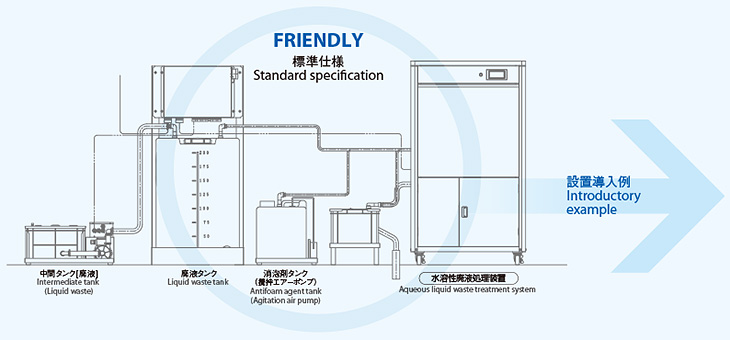

In order to acquire a higher effect – Installation layout image

Introductory example

Automation plan

An effect of its automation is demonstrated to reduction in cost by mitigation of labor load.

High cost-effectiveness

Reference example

- Days of operation for 1 month: 25 days

- Days of operation for 1 year: 300 days

- Discharge amount of wastewater: 100L/day

- Industrial waste disposal rate: JPY75/L

Before installation

Wastewater disposed by an industrial waste disposal company

Amount of wastewater

Amount of wastewater for 1 month: 2,500L

Amount of wastewater for 1 year: 30,000L

Industrial waste disposal expense

Disposal expense for 1 month: JPY187,500

(Amount of wastewater for 1 month x disposal rate)

Disposal expense for 1 year: JPY2,250,000

After installation

FRIENDLY: CT-AQ5H

Ex) Concentration rate: 6 / Electric rate: JPY12/kwh

Amount of wastewater

Amount of wastwwater for 1 month: Approx. 428L Approx. 1/6

Amount of wastwwater for 1 year: Approx. 5,138L Approx. 1/6

Electric rate

Usage for 1 month: JPY13,398 (Approx. JPY536 per day)

Usage for 1 year: JPY160,772

Antifoam agent

Month’s purchase: JPY8,300

Year’s purchase: JPY99,600

When clean water meets environmental quality standards for sewage, it can be drained into sewage system.

Furthermore, it leads to cost mitigation of water cost by reusing.

Cost comparison

Before installation

JPY187,500/ month

JPY2,250,000/ year

After installation

JPY53,798/ month Cost difference JPY133,702/ month

JPY645,722/ year Cost difference JPY1,604,278/ year

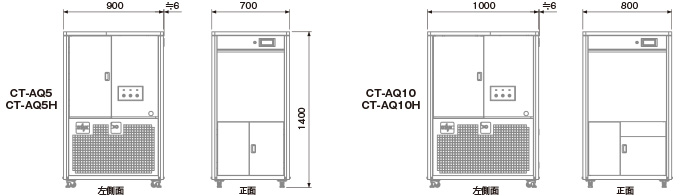

Specifications

| FRIENDLY | Heater type | Heat pump type | Heater type | Heat pump type |

|---|---|---|---|---|

| Model | CT-AQ5 | CT-AQ5H | CT-AQ10 | CT-AQ10H |

| Capacity | 5L/h | 10L/h | ||

| Power supply | 3phase 200V 50/60Hz | |||

| Electric power capacity / current |

Approx. 7.2KVA / Approx. 20.7A |

Approx. 4.4KVA / Approx. 12.7A |

Approx. 10.6KVA / Approx. 30A |

Approx. 5.2KVA / Approx. 14.9A |

| Process Scheme | Reduced-pressure distillation method | |||

| Target wastewater | Water-soluble wastewater | |||

| Dimension (W×D×H)mm |

700×900×1400mm | 800×1000×1400mm | ||

| Product weight | Approx. 240kg (Operation weight: Approx. 280kg) | Approx. 260kg (Operation weight: Approx. 320kg) | ||

| Operation condition | Ambient air temperature: 5~35℃, Humidity: 0~60% (Non condensing) | |||

| Standard accessories | Liquid waste tank (200L)x1, Antifoam agent tank (20L)x1 | |||

| Concentrated liquid waste tank (18L)x2, Renovated water tank (35.7L)x1 | ||||

| Liquid waste intermediate tank x1 | ||||

| Consumables | Antifoam agent (We recommend you to use our recommended agent.) | |||

Options

- Liquid waste intermediate tank (For additions)

- Renovated water intermediate tank

- Concentrated liquid waste tank

- Renovated water pH display

- Renovated water pH control (pH adjusting function by aeration)

* It needs to be adopted with the renovated water pH display.

Lineup of new models developed for power-saving technology

Power consumption is less than half that of conventional model

Heater type

CT-AQ5

Approx. 40%

DOWN

Heat pump type

CT-AQ5H

Heater type

CT-AQ10

Approx. 63%

DOWN

Heat pump type

CT-AQ10H

Dimensional drawing