DESTIMAT LE

Vacuum distillation with natural circulation and vapor compression

The efficient treatment of waste water. Vacuum distillation system with natural circulation

The DESTIMAT® LE series features different models from 9,323 ft³ to over 812,237 ft³ wastewater per year.

Features

KMU LOFT systems “Made in Germany” clean wastewater in leading industrial companies all around the world. They develop innovative solutions for the treatment of wastewater and fluids based on our patented vacuum evaporator technology to protect that resource.

DESTIMAT LE works according to the principle of natural circulation with targeted use of heat and circulation in a shell-and-tube heat exchanger. Due to the maximum heat recovery, the evaporator plant convinces with a very low energy consumption. Optimum accessibility, state-of-the-art control and touch panel guarantee maximum ease of operation.

No heaters

or pumps

Fully automated

effective cleaning

system

Best

lifecycle

costs

A lot of

Major enterprise

user

Our system solutions for your resource and cost management.

Resources are limited. Do you know how much potential is in your waste water? The professional management of wastewater protects the environment and can improve your company’s balance sheet.

|

Economical

|

Ecological

|

Typical foelds of industry

For most variable waste water

Typical fields of industry)〇Metal working, metal production 〇Surface engineering 〇Automotive, aerospace technology 〇Energy production and supply 〇Waste disposal, recycling, restructuring 〇Pharmaceutical, chemical, cosmetics, petrochemistry industry 〇Food and beverage production

KMU LOFT offers a range of effective pre-treatment and post-treatment options for process water and distillate, e.g.

Customers trust LOFT system solutions.

They have the expertise in over 2.400 successful

projects in more than 50 countries.

Waste water treatment using evaporator technology

|

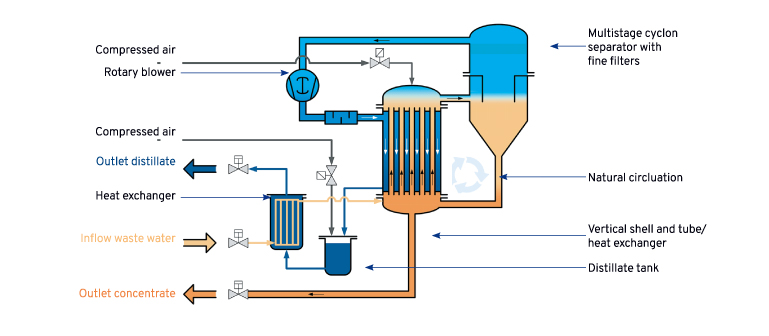

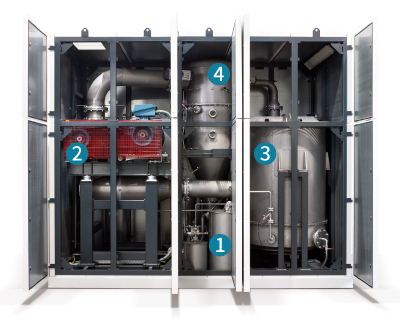

❶Pre-heat exchanger Incoming waste water is pre-heated by outgoing distillate. ❷Vacuum pump Water vapor is compressed, heated and pressed into the heat-exchanger. |

Evaporator  |

❸Heat-exchanger Hot steam heats up the waste water and condensed to distillate. The waste water evaporates and enters the cyclone. ❹High-performance cyclone separator Vapour is cleaned from ultrafine particles. |

Advantages of the evaporator

- For most variable waste waters

- Capacity 84-3,850 l/h

- Fully automatic cleaning

- High-quality materials

Specification

| model | LE70 | LE90 | LE100 | LE120 | LE150 | LE200 | LE250 | LE300 | LE400 |

| Capacity(L/h) | 84 | 108 | 120 | 144 | 180 | 230 |

285 |

345 | 460 |

| Installed power(㎾) | 7.5 | 11 | 15 | 22 | 30 | 37 | |||

| Weight empty (㎏) |

1000 | 1750 | 2100 | 3400 | |||||

|

Dimesion(㎜) L×W×H |

1900×1000 ×1880 |

2000×1200 ×2200 |

2413×1200 ×2670 |

2900×1400 ×2890 |

|||||

| Energy consumption (kwh/㎥) starting from |

~60 | ~60 | ~55 | ~50 | ~50 | ||||

| Type of model | LE 500 | LE 700 | LE 1000 | LE 1200 | LE 1400 | LE 2000 | LE 2200 | LE 3000 | LE 3500 |

| Capacity(L/h) | 575 | 805 | 1100 | 1320 | 1540 | 2200 | 2420 | 3300 | 3850 |

| Installedpower(㎾) | 45 | 55 | 90 | 132 | 200 | ||||

| Weight empty(㎏) | 4800 | 7300 | 7570 | 13800 | 17000 | ||||

| Dimensions L×W×H(㎜) | 3700×1820×3390 | 4840×1880×3390 | 5800×2330×4220 | 5910×2432×4220 | |||||

| Energy consumption (kwh/㎥) starting from |

~40 | ~35 | ~35 | ||||||

※Date for particular process waters are determined in customer specific calculations

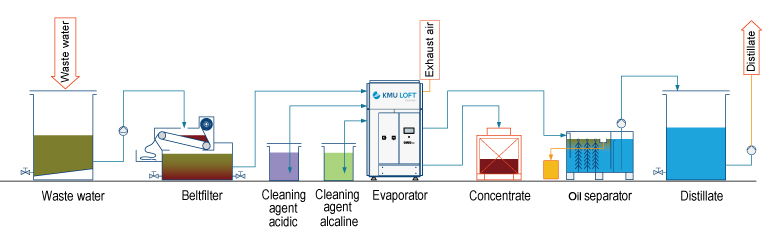

Flow diagram(waste water-soluble cutting oil)