EPS Electrostatic Powder Spray

Powder adheres to sheets uniformly more efficiently in the action of Coulomb force. Humidity inside the printing machine is fed back and voltage is controlled the optimal.

Powder adheres to sheets uniformly more efficiently in the action of Coulomb force. Humidity inside the printing machine is fed back and voltage is controlled the optimal.

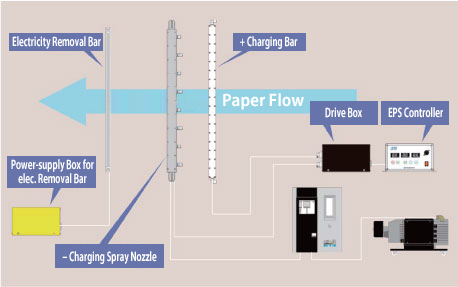

Brief Overview

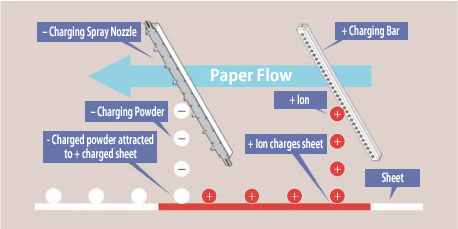

- Powder and sheet are electrified in reverse polarity, respectively. Powder and sheet gravitate toward one another and the sticking fraction of powder improves. Moreover, the powder which had dispersed until now also adheres to sheet by electrifying the powder itself.

- Negative charged powder particles are repulsive to one another and thus powder disperses more uniformly on the sheet.

- Unlike the air pressure-based CHP models, EPS utilizes a brand new system based on the Coulomb force as well as air pressure, and achieve a further reduction of powder scattering and consumption.

- To maximize Coulomb force’s effect, EPS adjusts charged voltage according to humidity inside the printing machine.

New Function

- The non-contact electrification method which is sheet is electrified positively by spraying + ion.

- The safe powder electrification method which electrifies the powder itself without corona discharge.

- Voltage is controlled according to the humidity in a printing machine.

Features

- Trouble-free in order not to contact sheet through the operation process

- Since powder and sheet gravitate toward one another, powder adheres to sheet efficiently.

- The amount of the powder used is reduced dramatically.

Specifications

| Name | EPS | |||

|---|---|---|---|---|

| Model | EPS-6 | EPS-8 | EPS-10 | |

| Adaptable Press | 26 “ & 28”/29” | 32” & 40” | 44” & 50” | |

| Components | CHP: Main Body, Electric Box, Spray Bar & Blower Pump | |||

| EPS: Controller, Drive Box, + Charging Bar & Ring Blower | ||||

| Metering Method | Speed Controlled Metering Roller | |||

| Quantity Control | Amount of Powder Spraying Self-Adjustment (Corresponding Speed 3,000 ~ 20,000 sheet/ h) |

|||

| Charging Method | Positive Charging (Sheet): Spraying Positive Ion (Non-contact) | |||

| Negative Charging (Powder): Contact Charging | ||||

| Power Supply | CHP: 3-Phase 200V | |||

| EPS: Single –phase 100 ~ 264V | ||||

| Current | Approx. 6.8A | Approx. 8.2A | ||

| Capacity | Approx. 2.3kVA | Approx. 2.8kVA | ||

| Dimensions | CHP Main Body | 320×200×420 (mm) | ||

| Electric Box | 250×100×225 (mm) | |||

| Nozzle Bar | 790/830×52×111 (mm) | 930/1130×52×116 (mm) | 1230/1410×52×121 (mm) | |

| Blower Pump | 467.4×290.4×353.9 (mm) | 630×328×342.9 (mm) | ||

| EPS Controller | 187×90×139 (mm) | |||

| Drive Box | 380×104×240 (mm) | |||

| Charging Bar | 766/814×42×54 (mm) | 910/1126×42×54 (mm) | 1198/1390×42×54 (mm) | |

| Ring Blower | 500×350×295.6 (mm) | |||